Thermal insulation technology of buildings using KREISEL is a modern and complex technology used for the construction of new buildings and the renovation of old ones, as well as insulating all types of exterior walls. It consists of attaching a layer of thermal insulation (polystyrene foam or mineral wool plates) to walls using KREISEL special adhesive (Vollwarmeschutz), EJOT fasteners, profiles and EJOT armature net installed on KREISEL special adhesive and priming and doing the finishing work with mineral or synthetic render by KREISEL.

The advantages and economic benefits of the KREISEL insulation technology are as follows:

- if the thermal insulation technology is used for the construction of a new building and for drawing up its budget, then the building costs will decrease;

- the thickness of the walls to be built and the foundation can be reduced to its minimum level;

- it is not necessary to use regular construction render;

- due to the reduction in the thickness of the walls, the useable surface area of the building will increase;

- a heater with less power can be used to heat the building;

- it will save energy;

- depending on the desired level of insulation, the insulation layer can be adapted for different building sites; saving not only the energy but also improving the quality of the building;

- in a residential building there will be a healthy and stable climate – cool in summer and evenly warm in winter;

- thermal insulation of exterior walls reduces temperature fluctuations and this, in turn, leads to a decrease in the „tension“ of walls thus reducing the risk of wall cracks.

Thin-coat render systems

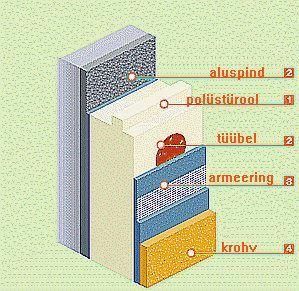

Thin-coat render systems consist of polystyrene foam or mineral wool that is glued to the substrate and fastened with dowels, if necessary and then covered with reinforcement layers. Reinforcement layer consists of a mineral putty and a glass-fiber net drowned into it. It will be covered with quartz sand primer. As a finishing material different rendering structures can be used (mineral render, polymer render, silicone render, silicate render, mosaic render). The system includes various auxiliary materials such as cap tracks on which polystyrene foam is rested on and strengthened lower-edge is made. In addition, a variety of window and corner profiles, polyurethane gaskets and others are also used. Clean and rendered concrete surfaces are suitable for the surface of the system as well as clay masonry, gas concrete (Aeroc, Siporex), Fibo and mineral construction plates (Magrock). The substrate tolerance must not exceed 2 cm. For better microclimate, we recommend using mineral wool plates instead of foam polystyrene in the living spaces, because the mineral wool “breathes” better. Nobody wants to live in a greenhouse where the air does not circulate and the ventilation is insufficient. However, if you choose to use foam polystyrene for insulation, then be sure to check if the existing ventilation system is adequate or you must additionally install fresh air valves. If the ventilation does not work properly, moisture will accumulate in the living space and there may be a risk of mould, which is not healthy. Different types of mushrooms and moulds affect both health and house structures.

Thin-coat render systems consist of polystyrene foam or mineral wool that is glued to the substrate and fastened with dowels, if necessary and then covered with reinforcement layers. Reinforcement layer consists of a mineral putty and a glass-fiber net drowned into it. It will be covered with quartz sand primer. As a finishing material different rendering structures can be used (mineral render, polymer render, silicone render, silicate render, mosaic render). The system includes various auxiliary materials such as cap tracks on which polystyrene foam is rested on and strengthened lower-edge is made. In addition, a variety of window and corner profiles, polyurethane gaskets and others are also used. Clean and rendered concrete surfaces are suitable for the surface of the system as well as clay masonry, gas concrete (Aeroc, Siporex), Fibo and mineral construction plates (Magrock). The substrate tolerance must not exceed 2 cm. For better microclimate, we recommend using mineral wool plates instead of foam polystyrene in the living spaces, because the mineral wool “breathes” better. Nobody wants to live in a greenhouse where the air does not circulate and the ventilation is insufficient. However, if you choose to use foam polystyrene for insulation, then be sure to check if the existing ventilation system is adequate or you must additionally install fresh air valves. If the ventilation does not work properly, moisture will accumulate in the living space and there may be a risk of mould, which is not healthy. Different types of mushrooms and moulds affect both health and house structures.